32-NCY

4-Axis CNC Mill / Turn CNC Lathe

- L36 mm 1-3/8” Bar Capacity

- L18-Tools with 7-Driven Tools Standard

- L“C” Axis and “Y” Axis with 19” Travel

- L1,181 Inch per Minute Rapid Rates

- LParts Catcher and Chip Auger Included

$0.00 Down Financing

Machine Specifications

Axis Travel

|

CNC Controlled Axis |

4-Axis (X, Y, Z, C) with High-Performance C-Axis |

|

X-Axis Travel (Vertical Tool) |

7.5” (190 mm) Linear Ways |

|

Y-Axis Travel (Cross Tool) |

19.3” (490 mm) Linear Ways – True Y-Axis |

|

Z-Axis Travel (Sliding Headstock) |

6.5” (165 mm) Linear Ways |

|

C-Axis Travel (Rotational Axis) |

360 degrees (360,000 Radial Positions) |

Spindle

|

Spindle Bore |

1.456” (37 mm) |

|

|

B&S#22 or Traub A-32 Collet Capacity |

1.25” (32 mm), 1-3/8” (36 mm) Collet Adapter Available |

|

|

Spindle Speed Range |

100 – 6,000 RPM |

|

|

Spindle Horsepower |

10 HP 3,000 RPM Spindle Motor (2:1 Pulley Ratio) |

|

|

Spindle Center Height |

38” (965 mm) |

|

|

Rigid Tapping on Main Spindle |

Yes |

|

|

Spindle bearing (Ø110mm) |

5 Ball Bearing Spindle, 3 Front & 2 Rear Bearings |

Tooling System

|

Number and Size of Turning Stations |

6 Tools of 1/2” or 12 mm (5 stations of 5/8” Optional) |

|

Number of Internal Static Tools |

5 ID Tool Stations (25 mm Bores) for Tool Bushings/Collets |

|

ID Tool Bores (Round Shank) |

25 mm Bore for ER-20 Collet, Split or Solid Tool Bushings |

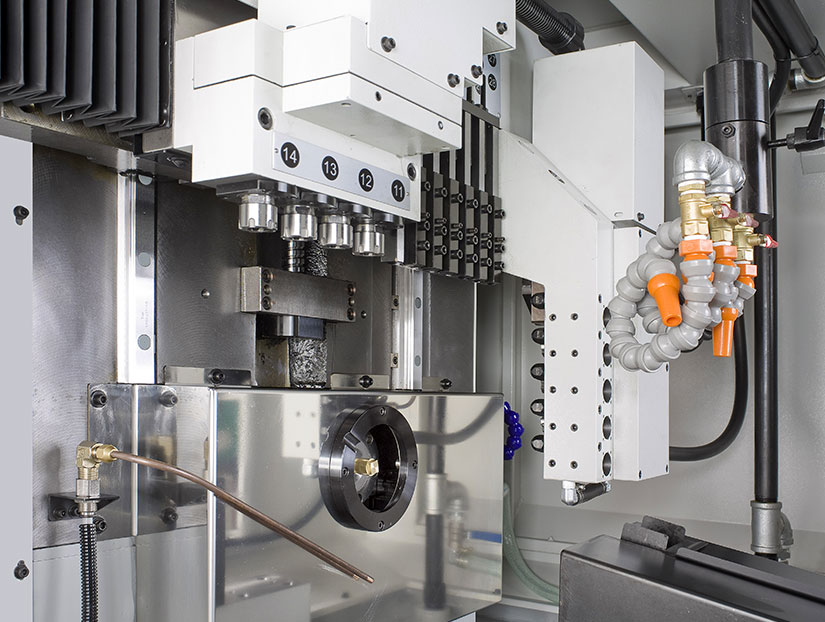

Driven Tool System

|

Number of Cross Working Driven Tools |

4 Cross Driven Tool Stations with ER20 Collet Holders |

|

Number of End Working Live Tools |

3 Axial Driven Tool Stations with ER20 Collet Holders |

|

Size of Driven Tools (Round Shank) |

ER-20 Collet Capacity (1/16” –1/2”) (1-13 mm) Diameter |

|

Rigid Tapping with Driven Tools |

Included for Main Spindle and Driven Tools |

|

Driven Tool Programmable Range |

0 – 4,000 RPM – Step-Less Speed Range |

|

Driven Tool HP |

Radial 2.0 HP (1.5 kw), Axial 1.0 HP (0.75 kw) |

Axis Drives

|

Rapid Travers Rate – X, Y, & Z axis |

1,181 IPM (30 m / min) |

|

Maximum Federate for Thread Cutting |

236 IPM (6 m / min) |

|

Minimum Programmable Input |

0.0001” (0.001 mm = 40 millionths of an inch) |

|

C-Axis Resolution |

0.001 degree (360,000 Radial Positions) |

|

Brushless AC Servo Motor Drive |

X = 2 HP (1.5 kw), Y&Z = 1.5 HP (1.0 kw) |

|

Ballscrew Diameter |

25 mm Diameter – 10 mm Pitch Double-Nut Ballscrews |

System Requirements

|

Electrical Requirements |

16 kVA – 42 amps @ 220 vac ±5% 3 Phase |

|

Pneumatic Requirements |

85 PSI @ 10 cfm for Parts Catcher and Spindle Brake |

|

Hydraulic System Capacity |

10 gallon (40 liter) Hydraulic Tank, 500 PSI Pressure |

|

Coolant Pump Motor / Tank Capacity |

3/4 HP w/ Flow Sensor / 50 gallon Tank with Dual Filtration |

|

Automatic Metered Lubrication system |

3 – 6 cc/ 15 min (Adjustable Lubrication Flow Rate) |

Machine Dimensions

|

Floor Space – L x W x H |

86” x 74” x 76” (2,176 x 1,858 x 1,919 mm) |

|

Machine Spindle Center Height |

38” (965 mm) |

|

Machine Net Weight |

6,172 lbs (2,800 kgs) |

U.S.A. Headquarters

Our headquarters is located in Chatsworth, California.

Showroom

Our warehouse features a large 4,000 sq. ft. showroom

Full Customer Support

Fully stocked parts room and training/simulation rooms

Competitive Financing

We offer competitive financing through our partnering company

Stay

Updated

Sign up for our monthly newsletter to stay updated with Expand Machinery news and information.

Machine Info

Take a moment to fill this out and one of our team members will send you information about this machine.

Expandmachinery.com | 818.349.9166 | Copyright © 2015-2024 Expand Machinery, LLC. All Rights Reserved.