78-TTMY

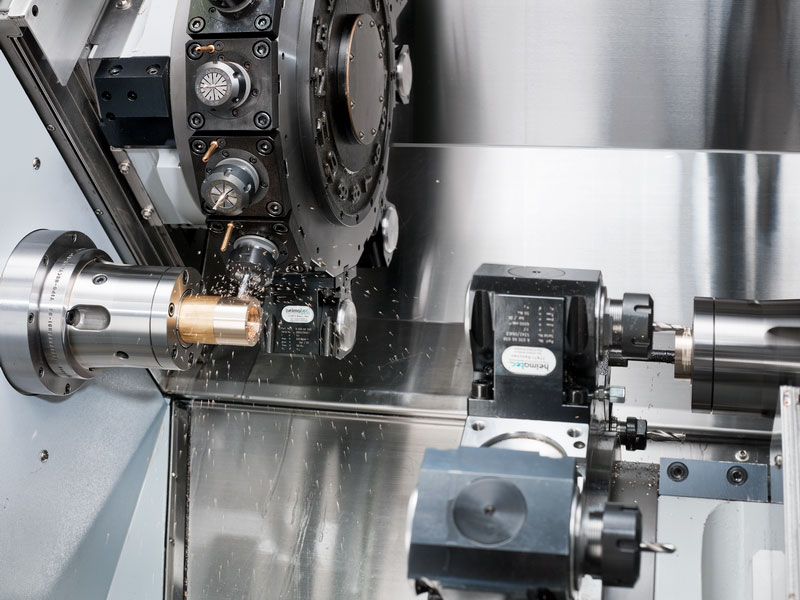

8-Axis Mill / Turn Lathe with Twin 16-Tool Turrets

- L78 mm 3” Bar Capacity

- LTwin 4,000 RPM Opposed Spindles

- LGlass Scale Feedback on X1 & X2 Axes

- L32-Driven Tool Positions each station can mount multiple tools

- L“Y” Axis with 3.936” Travel

- LSimultaneous Main & Sub-Spindle Machining

$0.00 Down Financing

Machine Specifications

Capacity

|

Turning Diameter |

7.48” (190 mm) maximum, 6.7” (170 mm) standard |

|

Turning Length / Center Distance |

15.75” (400 mm) / 36.22” (920 mm) between centers |

Main Spindle / Sub-Spindle

|

Spindle Nose / Bearing Diameter |

A2-6 |

|

Spindle Bar Capacity |

3.08 |

|

Chuck Size (Optional) |

8” with 68 mm bore |

|

Spindle Center Height |

46.45” (1,180 mm) |

|

Maximum Spindle Speed |

60 – 4,000 RPM (Integral Spindle) |

|

Spindle Motor Horsepower |

30 HP peak, 20 HP (30 min duty rating) |

|

Sub Spindle Motor Horsepower |

20 HP peak, 15 HP (30 min duty rating) |

Live Tool Turrets

|

Number of Turret Stations |

32 (Any combination of 32 ID, OD or Live tool stations) |

|

Index Time (Adjacent Tool / 180° index) |

0.2 seconds / 1.2 seconds High-Speed Servo Indexing |

|

Live Power Tool / RPM |

7 HP / 6,000 RPM, 14.75 ft. lbs torque (20 Nm) |

|

Tool Size / Collet Size |

25 mm (for square tool and round tool) / ER-32 |

|

Tool Holder Type & Size |

BMT-65 Base Mount Tooling |

Y, C, & B-Axis

|

Y-Axis Travel |

3.93” of Travel – ±1.968” off of Centerline (±50mm) |

|

Y-Axis Rapid Feed Rate |

236 Inch Per Minute (6m per minute) |

|

|

|

|

C-Axis Spindle Radial Resolution |

360,000 Radial Positions with Full Contouring Capability |

|

|

|

|

B-Axis Distance Between Spindles |

36” (914mm) |

|

B-Axis Rapid Traverse Rate |

1,573 Inch Per Minute (40m per Minute) |

|

B-Axis Travel |

25.59” (650mm) |

Axis Specifications

|

Axis Travel – X1, X2 – Axis |

X1 5.9” (150 mm), X2 9.05” (230 mm) with Glass Scale Feedback |

|

Axis Travel – Z1, Z2 – Axis |

Z1 17.32” (440 mm), Z2 17.32” (440 mm) |

|

Rapid Travers Rate – X1, X2 -Axis |

630 IPM (16 m / min) |

|

Rapid Travers Rate – Z1, Z2 – Axis |

1,573 IPM (40 m / min) |

|

Minimum Programmable Input |

0.0001” (0.001 mm = 40 millionths of an inch) |

Fluid Capacity

|

Hydraulic System |

10.5 gallons (40 Liters) with 3 HP (2.2 kw) Pump Motor |

|

Dual Coolant Pumps |

2x 1.7 HP Pumps for Tooling & 2 Pumps for Chip Flushing |

|

Coolant Tank |

70 gallon (280 Liters) Coolant Tank |

Specifications

|

Machine Weight |

22,751 lbs (10,320 kgs) |

|

Electrical Requirement |

49.5 kVA (220 vac ±5%, 3 phase, 60 Hz, 130 amps) |

|

Air Requirement |

85 PSI @ 8 cfm for Parts Catcher, Ejector, Oil Mist Lubricator |

|

Machine Dimensions |

Width 165” / Depth 88”/ Height 84” (Includes Chip Conveyor) |

U.S.A. Headquarters

Our headquarters is located in Chatsworth, California.

Showroom

Our warehouse features a large 4,000 sq. ft. showroom

Full Customer Support

Fully stocked parts room and training/simulation rooms

Competitive Financing

We offer competitive financing through our partnering company

Stay

Updated

Sign up for our monthly newsletter to stay updated with Expand Machinery news and information.

Machine Info

Take a moment to fill this out and one of our team members will send you information about this machine.

Expandmachinery.com | 818.349.9166 | Copyright © 2015-2024 Expand Machinery, LLC. All Rights Reserved.