products | GANESH | GTW-30 CNC

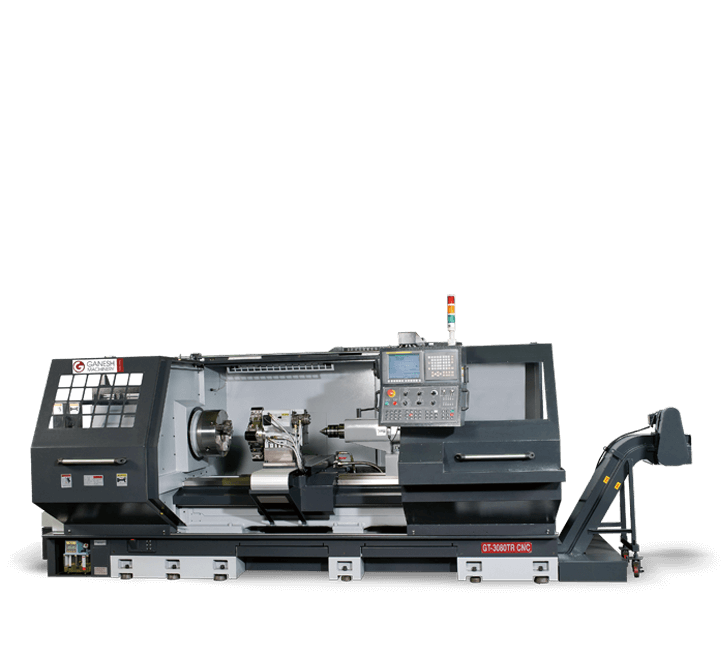

GTW-30 CNC

30” Heavy Duty CNC Big Bore Lathe

- LA2-11 Spindle w/ 6-5/8” Bore

- L10 - 1000 RPM Standard

- LA2-15 Spindle w/ 10” Bore, 18 - 600 RPM Optional

- L2-Gear Ranges for Increased Cutting Torque

- L8-Station Tool Turret – Any combination of ID/OD tools

- LDual-Turrets ( Front & Rear of cross slide ) Available

$0.00 Down Financing

Machine Specifications

Capacity & Dimensions

|

Swing over Bed |

30″ |

(760 mm) |

|

Turning Diameter (in front of cross slide w/8 station turret turning tool |

22″ |

(560 mm) |

|

Swing over Cross-Slide (turning diameter over cross-slide) |

19″ |

(480 mm) |

|

Center Height |

15″ |

(380 mm) |

|

Bed width of ways |

18″ |

(460 mm) |

|

Bed Casing Height |

15.75″ |

(400 mm) |

Spindle

|

Spindle Motor Horsepower (Fanuc 15 Kw – 18 Kw) |

30 HP |

(25 HP 30 min rated) |

|

Spindle Speeds |

10 – 1,000 RPM |

|

|

Spindle Gear Ranges – 2 automatically selected gear ranges |

L = 30 – 300 RPM |

H = 10 – 1000 RPMS |

|

Spindle Bore (10″ bore optional) |

6.69″ |

(170 mm) |

|

Spindle Nose (front & rear) / bearing |

A2-11 / Taper Roller Bearings |

|

|

Spindle Torque for 6 5/8″ bore – low gear / high gear |

1,180 / 346 ft lbs |

(1,600 / 470 Nm) |

|

Big-Bore Spindle Option – Bore Size |

10″ (255 mm) |

A2 – 15 spindle |

|

Big Bore Spindle Speeds |

18 – 600 RPM in 2 ranges |

|

|

Big Bore Spindle Gear Ranges |

Low 18 – 186 RPM |

High 60 – 600 RPM |

|

Big Bore Spindle Torque for 10″ bore – low gear/high gear |

1,475 / 442 ft lbs |

(2,000 / 600 Nm) |

Axis

|

Rapid Traverse Feedrate X & Z |

394 IPM |

(10 m / min) |

|

X-Axis Cross Slide Travel |

19 5/8″ |

(500 mm) |

|

Z-Axis Travel (listed with each bed length) |

||

|

X-Axis Ballscrew Diameter / Servo Motor Power |

1.25″ (32 mm) |

2.0 HP (1.6 kw) |

|

Z-Axis Ballscrew Diameter / Servo Motor Power |

2″ (50 mm) |

4.0 HP (2.9 kw) |

|

X-Axis Thrust |

2,020 lbs |

(920 kgf) |

|

X-Axis Thrust |

3,020 lbs |

(1,370 kgf) |

|

Cross Slide Dimensions W x L |

39″ x 10″ |

(1,000 mm x 258 mm) |

|

Minimum input unit |

0.0001″ |

(0.001 mm = 40 millionths) |

Tool Turret

|

Hydraulic type / LS-200R |

||

|

Tool stations – any combination of ID / OD tooling / Index time |

8 stations |

|

|

OD Tooling (additional ID & OD tool holders in stock) |

1″ tools w/ 8 tool clamps provided |

|

|

ID Tooling (40mm when specified for metric users) |

4 ID (1.5″ bore) holders provided |

Tailstock

|

Air-Assisted Manual Positioning – Quill engraved with inch/metric quill graduations |

||

|

Quill Diameter |

4.92″ |

(125 mm) |

|

Quill Stroke (manual quill advance, hydraulic optional) |

7.87″ |

(200 mm) |

|

Quill Taper |

MT-6 |

Morse Taper #6 |

|

Tailstock body set-over adjustment |

±0.4″ |

(±1 mm) |

Electrical / Hydraulic / Coolant

|

Power Requirements – FANUC 0i – TF control, motors & drives |

30 kVA / 220 vac / ±5% |

|

|

Hydraulic Motor Power |

2 HP |

|

|

Hydraulic Pressure |

435 PSI / Mobil #32 oil |

|

|

Coolant Pump |

3/4 HP |

|

|

Machines need stable 220 volts, 3 Phase – Please use appropriate transformers or voltage stabilizers |

U.S.A. Headquarters

Our headquarters is located in Chatsworth, California.

Showroom

Our warehouse features a large 4,000 sq. ft. showroom

Full Customer Support

Fully stocked parts room and training/simulation rooms

Competitive Financing

We offer competitive financing through our partnering company

Stay

Updated

Sign up for our monthly newsletter to stay updated with Expand Machinery news and information.

Machine Info

Take a moment to fill this out and one of our team members will send you information about this machine.

Expandmachinery.com | 818.349.9166 | Copyright © 2015-2024 Expand Machinery, LLC. All Rights Reserved.