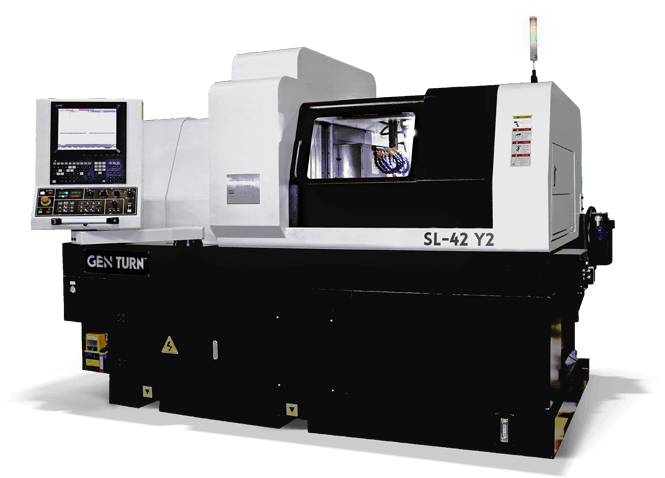

SL-42Y2

Hybrid 42 mm 8-Axis CNC Swiss Machine

- LBar Capacity to Ø1-5/8”

- LDouble “Y” Axis and Double “C” Axis

- LSimultaneous Main & Sub-Spindle Machining

- L30-Tools with 8-Driven Tools Standard

- LOptional Rotary Synchronous Guide-Bushing

- LHigh-Performance Mitsubishi M-830 Control

$0.00 Down Financing

Machine Specifications

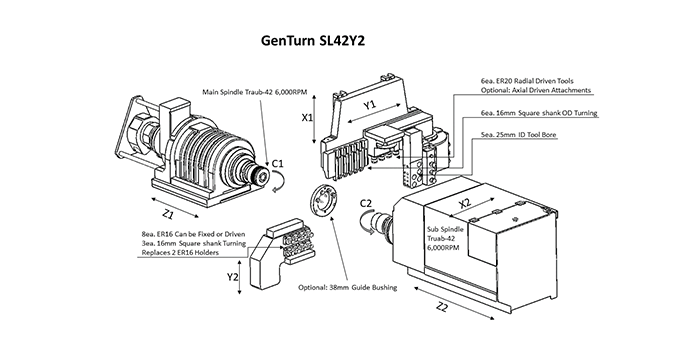

Main Spindle

|

Maximum RPM / Spindle Bearing |

6,000 RPM / 5 Bearing Spindle, 3 Front, 2 Rear Ball Bearings |

|

Main Spindle Servo Moto (5.5 / 7.5 kw) |

10 HP 15 min Duty Rated (7.5 HP Constant Duty Rated) |

|

Collet Style for Main & Subspindle |

Traub-42 / 173E |

|

Collet Closer Style |

Lever Action Collet Closer – Driven by Hydraulic Piston |

|

Guide Bushing Type |

Optional Rotary Guide – Bushing uses Hardinge STM38 Bushings |

|

Bar Diameter |

Ø1/4” – 1-5/8” (Ø5 – 42 mm) without Guide Bushing |

|

Maximum Turning Length (Rotary Bushing) |

12.20” Single Stroke (310 mm) (Rotary Guide Bushing Optional) |

|

Maximum Turning Length (without Bushing) |

4.13” (105 mm) |

|

Spindle Bore |

Ø1.732” (Ø44 mm) |

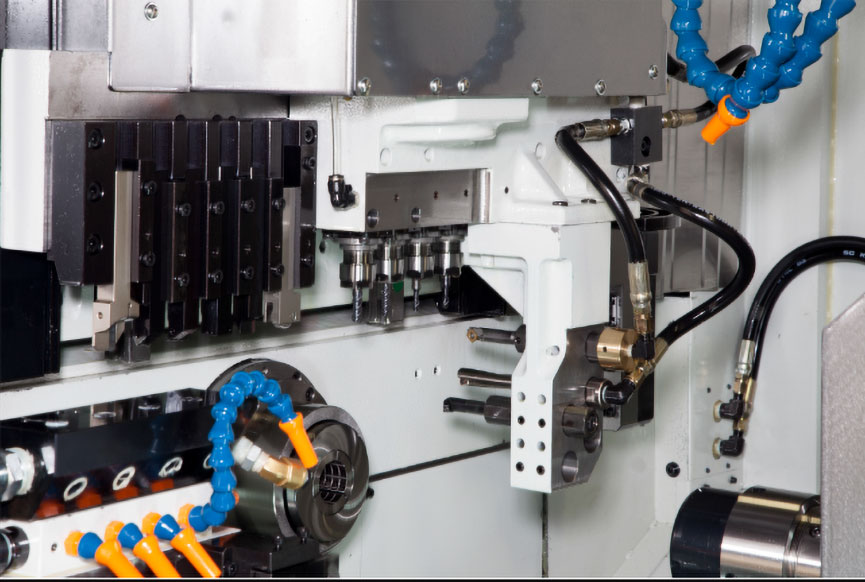

Main Spindle Tooling

|

OD Turning Tool Holders – S1 |

6 – 16 mm (5/8”) Square Shank Tool Holders |

|

|

ID Internal Tool Holders – S1 |

5 – 25 mm Shank Round Tool Sleeve Bores |

|

|

ID Deep Hole Drill Positions – S1 |

2 – 25 mm Shank Round Tool Sleeve Bores |

|

|

Cross Slide Live Tools – S1 |

6 – ER-20 Collet Chuck Spindles, 4,000 RPM, 2 HP (1.6 kw) |

|

|

Axial Front Slide Live Tool Option – S1 |

3 – ER-20 Front Axial Live Tools – Optional in lieu of 1 Cross Tool |

|

|

Maximum Drilling / Tapping Capacity |

13 mm Drilling / M10 Tapping |

|

|

Cross Drilling / Tapping Capacity Option |

10 mm Drilling Capacity / M6 Tapping |

Sub-Spindle

|

Sub-Spindle RPM / Spindle Bearing |

6,000 RPM / 4-Bearing – Quad Duplex Pair Configuration |

|

Main Spindle Servo Moto (2.2 / 3.7 kw) |

10 HP 15 min Duty Rated (7.5 HP Constant Duty Rated) |

|

Collet Style for Main & Subspindle |

Traub-42 / 173E |

|

Maximum Barstock Diameter |

1-5/8” (42 mm) (42 mm Parts can Through the Subspindle) |

|

Spindle Bore |

Ø1.732” (Ø44 mm) (uses Hydraulic Piston Lever Action Collet Closer) |

|

Finished Parts Ejector & Air Blast |

Included |

|

Maximum Workpiece Length for Front Ejection |

110 mm Maximum Part Length for Front Ejection from Subspindle |

Sub-Spindle Tooling

|

OD Turning Tool Holders – S2 |

3 – 16 mm Square Shank Turning Tool Holders |

|

ID Internal Tool Holders – S2 |

5 – 25 mm Shank Round Tool Sleeve Bores |

|

ID Internal Tool Holders – S2 (8 possible) |

3 – ER-16 Fixed Tools – Ø3/8” Max. |

|

Subspindle Axial Live Tools – S2 (8 possible) |

3 – ER-16 Axial Live Tools, 4,000 RPM, 1.0 HP (0.75 kw) |

|

(8-subspindle tool block can mix live & fixed tools, or 2 radial live tools can be substituted for 2 axial tools on subspindle tool block) |

|

|

Maximum Drilling / Tapping Capacity |

13mm Drilling Capacity / M10 Taping on Sub-Spindle |

|

Maximum Cross Drilling / Tapping Capacity |

8mm Drilling Capacity / M6 Tapping |

Axis

|

Main Spindle Stroke |

12.20” (310 mm) |

|

X1, Y1, Z1, X2, Y2, Z2 Rapid Traverse Rate |

944 IPM (24 m / min) |

|

X1, Z1 Axis Motor Power |

2 HP (1.4 kw) |

|

X2, Y1, Y2, Z2 Axis Motor Power |

1 HP (.75 kw) |

|

X1, Y2 Linear Ways |

Ball-Bearing Linear Ways (Point Contact) |

|

Z2, Y1, Z1, Z2 Linear Ways |

Roller-Bearing Linear Ways (Line Contact – Twice as Rigid) |

|

Minimum Input Unit |

0.0001” (0.001 mm = 40 millionths/inch) |

Specifications

|

Machine Dimensions (L x W x H) |

121” x 67” x 83” (2,925 x 1,690 x 2,100) + 29” for Conveyor |

|

Machine Weight |

11,024 lbs. (5000 kgs) |

|

Coolant Pump Power |

1-3/4 HP (1.3 kw) with Flow Confirmation Monitor |

|

Coolant Tank Capacity |

65 gallon Coolant Tank (250 L) (Cutting Oil Only, No Coolant) |

|

Lubrication Distribution (2-liter Capacity) |

Way Lube Distributed at 3 – 6 cc / 15 min Cycle |

|

Machine Power Requirements |

220 vac ±5%, 80 amps, 30 kVA, 3 phase, 60 Hz |

|

Air Requirements |

85 PSI at 6 CFM for Parts Catcher, Parts Ejector, & Air Blast |

U.S.A. Headquarters

Our headquarters is located in Chatsworth, California.

Showroom

Our warehouse features a large 4,000 sq. ft. showroom

Full Customer Support

Fully stocked parts room and training/simulation rooms

Competitive Financing

We offer competitive financing through our partnering company

Stay

Updated

Sign up for our monthly newsletter to stay updated with Expand Machinery news and information.

Machine Info

Take a moment to fill this out and one of our team members will send you information about this machine.

Expandmachinery.com | 818.349.9166 | Copyright © 2015-2024 Expand Machinery, LLC. All Rights Reserved.