Top Shops Machine Parts in One Operation

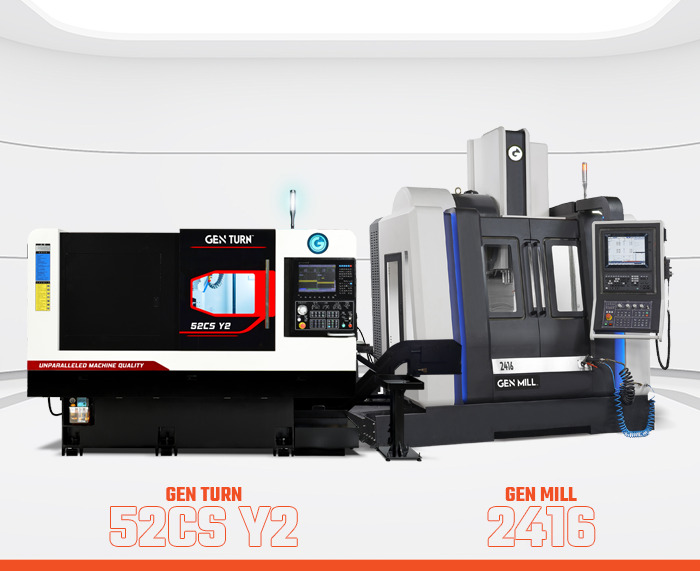

Be sure to see the GEN TURN 52CS Y2 8-axis Swiss Machine and the GEN MILL-2416 5-axis mill up close and personal at the IMTS booth 338048!

Shop owners are continuously searching for a competitive advantage, and the answer is often found in superior production efficiency. One critical facet in becoming a top shop in 2022 is completing a wide range of complex parts in just one work handling by combining operations to minimize labor and speed workflow. Parts that can come off the machine with all the features completed and deburred from barstock, with less human intervention, are a common benefit in turning applications when using multi-axis CNC lathes.

A 2” 8-axis Swiss mill/turn center featuring a subspindle & dual “C” & “Y” axes provide quick production of complex work in just one handling, with sufficient tool stations to get the job done efficiently in just one operation. It is an example that meets the criteria that top shops are looking for to provide unattended productivity that significantly enhances their return on investment. Achieving these benefits with the additional payback of having quick access to gang tooling reduces the critical tool-to-tool time for greater overall production efficiency. Shops long ago saw the benefits of having a subspindle on a CNC lathe. Still, the advent of the C-axis on both spindles enabled the work that needed milling features to be completed. A Y-axis followed this to expand the range of milling applications on turned work, and this was later trailed by simultaneous dual Y-axis ability in the quest for even greater productivity by milling with a separate Y-axis on the front and the back of the workpiece at the same time to complete the part in just one operation.

Having benefits of 5-axis machining in milling applications such as greater access to multiple workpiece surfaces to reduce setups, shorter tool extensions for enhanced cutting conditions, improved part dimensional quality, and faster throughputs; as well as the ability to machine more complex workpiece features provides a significant competitive advantage and increases productivity. Better surface finishes result by using the 5-axis capabilities on contoured geometry. Lower cycle times and costs are achieved because more material can be removed with each tool pass.

The “Gold Standard” in production machining is efficiently getting the work completed with a minimum of work handling. This done-in-one operation concept requires a sufficient tool count encompassing the redundant tooling necessary to benefit from the tool-life-management capability to keep the production flowing without interruption.

Done-in-One: Expand Machinery High-Value CNC Machines

The “done-in-one” theme is present throughout the Expand Machinery lineup of high-value CNC machines. Use our website contact form or call Expand Machinery at 818-349-9166 for a detailed quotation or information on other CNC milling or turning centers, as well as the Ganesh line of manual and CNC toolroom machines. See the full Expand Machinery lineup at www.expandmachinery.com.