Fast & Affordable 5-Axis Milling

There is no need to mess with multiple setups and manual repositioning of the workpiece, with the resultant degradation of part accuracy, when 5-axis machining allows you to approach the workpiece from all directions in just a single setup. The GenMill 5X-4 features a 4” diameter tilting and rotating worktable with zero-backlash roller gear cam operation for optimum repeatability. Working with materials ranging from titanium and stainless steel to, Kovar and Inconnel to produce body implants, surgical instruments, or a myriad of other medical components with the GenMill 5X-4 making the 5-axis game more affordable than ever.

The 5X-4 features a 12,000 RPM 7.5-horsepower dual-ground, dual-contact, “Big-Plus” spindle and offers 6,000 RPM tapping capability. The drum-style tool turret provides for 21-tools in BT#30 holders and changes tools in a blazing 1.6-seconds. The quick tool change time coupled with rapid traverse rates of 2,362 IPM make for exceptional production efficiency. The preloaded cross-roller bearing guideways provide greater stiffness, rigidity, load carrying capability than other guideway systems offer, providing both better surface finishes and improved tool life.

To obtain high productivity in 5-axis machining, paramount consideration has to be given to a CNC control and drive system that has the speed and responsiveness necessary to optimize machine performance. The GenMill 5X-4 is paired with the Mitsubishi M80 high-performance CNC controller featuring a 64-bit RISC processor and boasts a 135,000 block-per-minute processing speed, coupled with a 1,350 block-look-ahead capability and a massive 32GB solid-state data server making it one of the fastest controls in the industry. A 3-year Mitsubishi control, motor, and drive warranty is provided by the factory and backed by an extensive countrywide network of support.

20mm GENTURN Hybrid Swiss CNC Lathe

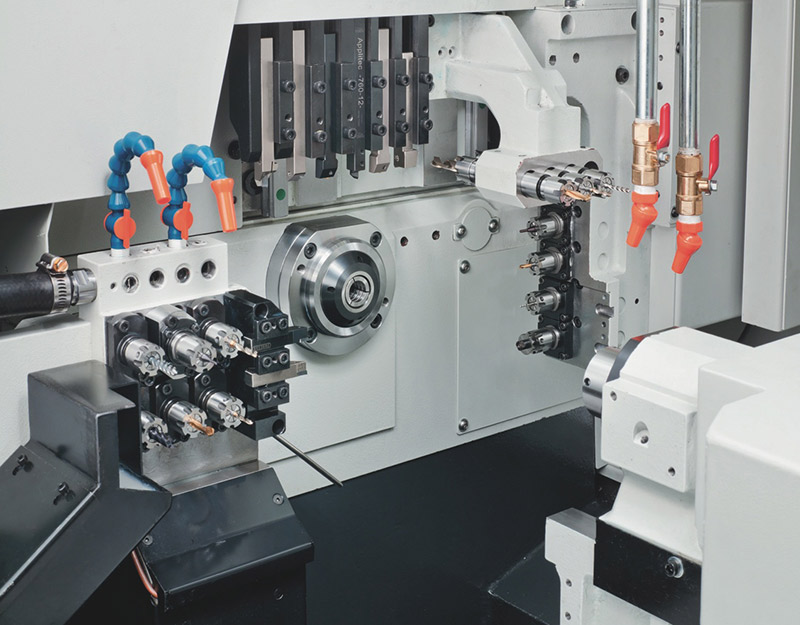

Expand Machinery specializes in providing their customers with superior production efficiency by completing complex parts in just one seamless operation. The GENTURN CNC Swiss lathe series, such as the twin-spindle GENTURN SL-20Y2 8-axis 20mm Swiss lathe, addresses the need of getting work up to Ø 3/4” done efficiently, in only one operation; with all of the axial and radial milling features accurately timed and deburred. Getting the work completed without building accuracy compromising fixtures for follow-on operations; and tying up multiple machines and operators, is the only way to really be really competitive in the modern machining world.

Dental machining and precision medical parts machining for screws, shafts, standoffs, inserts and many other components are suitable candidates for the highly efficient SL-20Y2 machine. The GENTURN SL-20Y2 can be operated with, or without, a guide bushing so you can make the most profitable choice of operating modes that provide the most efficient solution for each job. The 10,000 RPM main spindle is powered by a 5-horsepower spindle motor, the 5-horsepower sub-spindle turns at 8,000 RPM. A total of 30-toolholders are standard with the basic machine, of which 8-tools are driven and feature ER-16 collet spindles. The main spindle can bring 17-tools to work on the part, and the sub-spindle can utilize 13-tools in the basic machine configuration.

Many tooling options are available to address the specific tooling needs of each workpiece and to increase the overall tool count. Standard features include a high-performance C-axis with 0.001° resolution on both the main and subspindle for accurately timed axial and radial milling features. A parts catcher and parts conveyor are provided on to facilitate the careful mark-free removal of valuable parts from the machine. A cut-off confirmation sweep-arm switch is provided to ensure that the part is properly separated from the barstock curing cutoff. Cutting oil flow-confirmation monitoring is provided to ensure that the cutting oil is properly lubricating the cutting tools. A cutting oil chiller system is included to maintain thermal control of the cutting oil for consistent machine accuracy. All Expand Machinery machines are built in our modern ISO certified factory in Taiwan.

Expand Machinery also provides a 5-axis milling machine with a 12” platter as well as an extensive line of 3-axis milling centers from 24” x 16” up to 100” x 39”, drill/tap centers. The turning roster consists of CNC Swiss from 20mm to 52mm, multi-axis CNC turning centers, and the Ganesh lineup of manual and CNC toolroom machines. For a profession analysis of your needs call 818-349-9166 and let us help you with a productive solution that meets your machining requirements.