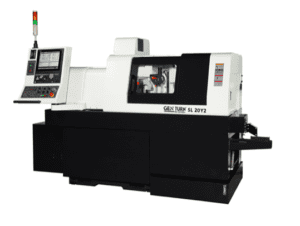

The GEN TURN Swiss SL 20Y2 machine uses a sliding headstock that feeds bar stock through a guide bushing in the Z-axis past the stationary cutting tool. This type of configuration means that the cutting tool always engages the bar stock close to the bushing and provides the greatest amount of support. The result will be to reducing vibration and tool deflection. The GEN TURN Swiss SL 20Y2 lathe will make long and slender workpieces for tighter tolerances.

The GEN TURN SL 20Y2 turning machines includes a sub-spindle for additional machining operations such as drilling and boring. With this ability, you eliminate the need to move the part from one machine to another and reducing overall production time, operator error, labor cost, and idle spindle time. This makes the GEN TURN a great choice.

One way to improve the productivity of your GEN TURN SL20Y2 Swiss machines is to add the right automatic bar feeder. This will allow continuous, unattended and even lights-out operation. The bar feeder also provides additional material support to further reduce vibrations and protect operators from exposed bar stock rotating at high speeds.

The GEN TURN SL 20Y2 is an 8-axis 20mm bar diameter sliding headstock CNC lathe with a Removable Synchronous Rotary Guide Bushing that offers the flexibility to efficiently run longer work with high length to diameter ratios, using the included synchronous rotary guide bushing. The SL 20Y2 will also run shorter work less expensively without the need for a guide bushing; with the bonus of not needing ground barstock and having much shorter bar remnants. This provides you the opportunity to make the most efficient and profitable choice of how to run the job depending on the specific application requirement.

The GEN TURN SL 20Y2 is very robust and rigid machine that can machine on the main and subspindle simultaneously for enhanced production efficiency. The heavy ribbed closed-box torque-tube casting machine weighs nearly 6,000 pounds! The lathe can have up to 38-tools with up to 23 live tool stations. There are 30-tool stations supplied with the basic machine. The standard Main Spindle tooling complement is 17 tools. There are 5-live ER-16 cross working spindles, 6-turning tool stations, and 6-fixed I.D. tool sleeves. The Back-Working Spindle has 13-tool stations standard including 3-axial ER-16 driven spindles, 3-fixed axial ER-16 tools, 4 fixed I.D. tool sleeves, and 3-turning tool stations. Many additional specialty tools can be added to meet the needs of a specific job.