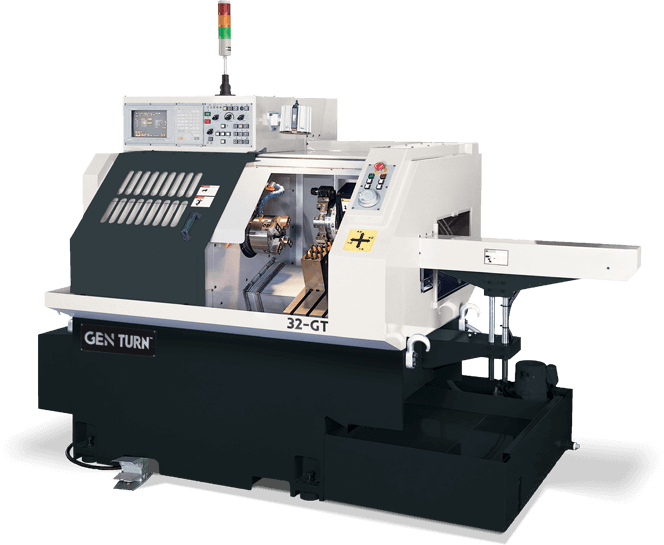

32-GT

2 or 3-Axis CNC Gang-Tooled Lathe

- L32 mm 1-1/4” Bar Capacity

- L6,000 RPM A2-5 Spindle

- L7.5 Horsepower

- LParts Catcher Standard

- LLive Tooling Options

- L8-Station Turret Optional

$0.00 Down Financing

Machine Specifications

Main Spindle

|

X-Travel |

8.46” (215 mm) |

|

Z-Travel |

5.98” (152 mm) |

|

Maximum Turning Diameter/Length |

7.87” / 5.5” (20 0mm / 140 mm) |

|

Swing Over Bedways |

12.59” (320 mm) |

Axis Feeds

|

Rapid Traverse – X, Z |

787 IPM 20 m / min |

|

|

Rated Cutting Feedrate |

236 IPM 6 m / min |

|

|

Mechanical Way System – X / Z |

Box Ways / Turcite® Coated & Pressure Lubricated |

|

|

Slant Bed Angle |

20º Slant Bed Angle for Tooling |

|

|

Axis Drive Motor Power – X-Axis |

1.0 HP .75 kw |

|

|

Axis Drive Motor Power – Z-Axis |

1-1/3 HP 1.0 kw |

|

|

Ballscrew Diameter – X, Z |

32 mm |

|

|

Positioning Accuracy – X / Z – X / Z |

±0.00015” / ±0.004 mm |

|

|

Positioning Repeatability – X / Z |

±0.00008” / ±0.002 mm |

|

|

Least Input Command Increment |

0.0001” / 0.000040” / 0.001 mm / (40-millionths in metric) |

Spindle

|

Spindle Nose Mount |

A2-5 |

|

Spindle Speed |

6,000 |

|

Maximum Tapping Spindle Speed |

2,000 RPM |

|

Maximum Bar Capacity |

1-1/4”, 32 mm |

|

Spindle Bore |

34 mm |

|

Spindle Bearing – Inside Diameter |

70 mm (80 mm Optional) |

|

Spindle Motor Power – 3.7 / 5.5 kw |

7.5 HP / 5.5 kw (10 HP 7.5 kw Spindle Motor Optional) |

|

Spindle Motor Torque |

26 ft. lbs 35 Nm |

|

Spindle Motor Drive Coupling |

Belt Drive |

|

Spindle Runout |

≤ 0.000040” T.I.R. |

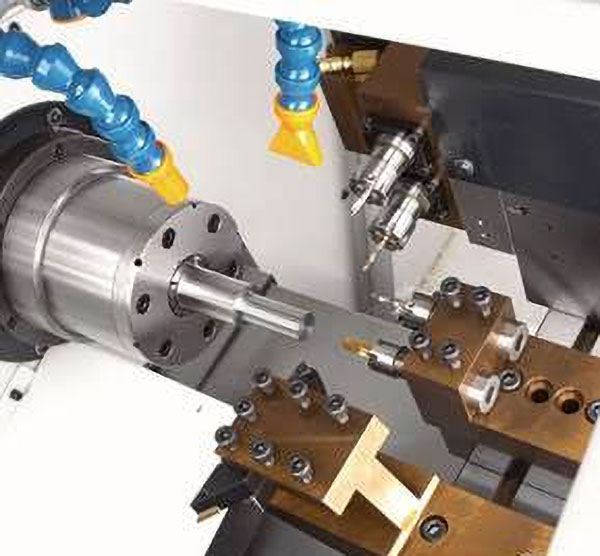

Tool Plate / Tool System

|

Tool Plate Overall Dimensions |

8.66” x 36.45” / 220mm x 706mm |

|

Tool Plate T-Slot Dimensions |

21mm Base & 12mm Neck Width, (8mm Base Height /17mm total) |

|

T-Slots |

3 T-Slots on 63mm Centers (See Power Point for Drawings) |

|

Turning Tool Shank Size |

20mm 3/4” Square Shank |

|

Internal Tool Shank Size |

32mm 1-1/4” (25mm for Optional Tool Turret Bores) |

|

Optional Driven Tool Horsepower (.75kw) |

1-Horsepower with 2:1 Speed Reduction for Increased Torque |

|

Optional Driven Tool Collet Size (1/2”) |

2-ER20 Collets in a Hydraulic Positioned Upper/Lower Format |

Specifications

|

Air Service Requirements |

85 PSI @ 5 scfm / 5.5 kg / cm² |

|

Electrical Requirements – Connected Load |

10 kVA, 28 amps, 220 vac ±5%, 60 Hz |

|

Coolant Tank Capacity / Motor Power |

21 gallons / 1/2 HP / 80 Liters / 2 amps |

|

Lubrication Pump |

150 watts |

|

Hydraulic Pump Motor / Pressure |

1 HP / 500 PSI / .75 kw / 32 bar |

|

Floor space requirements (W x D x H) |

81” x 64” x 64” / 282 x 135 x 183 cm (+ Chip Conveyor) |

|

Machine Weight |

4,850 pounds (2,200 kg) |

|

Warranty – 1-year machine warranty |

3-year Mitsubishi Control, Motors, & Drive Warranty |

U.S.A. Headquarters

Our headquarters is located in Chatsworth, California.

Showroom

Our warehouse features a large 4,000 sq. ft. showroom

Full Customer Support

Fully stocked parts room and training/simulation rooms

Competitive Financing

We offer competitive financing through our partnering company

Stay

Updated

Sign up for our monthly newsletter to stay updated with Expand Machinery news and information.

Machine Info

Take a moment to fill this out and one of our team members will send you information about this machine.

Expandmachinery.com | 818.349.9166 | Copyright © 2015-2024 Expand Machinery, LLC. All Rights Reserved.