The accompanying video shows the GEN TURN 52 GTS dual slide 6-axis CNC lathe from Expand Machinery in Chatsworth, CA, using a thread rolling head. The precision thread is rolled on each end of the shaft in the same time it takes to make one pass using a single-point tool, which results in a 90% (or more) cycle time reduction!

A rolled thread is more precise and consistent than a cut thread, eliminating the need to waste time while closely monitoring multi-pass thread cutting production. By eliminating the need for constant size adjustments, set-up and downtime costs are reduced, resulting in significant cost savings. On a cost-per-piece basis, thread rolls cost less than the carbide inserts utilized in single-point thread cutting.

The burnished thread surface, with a roughness level of below 32-micron, improves resistance to corrosion and reduces abrasion within the thread. Because minimal abrasion occurs when thread rolling, profile accuracy increases. The work-hardened flank provides increased surface tensile strength, shear strength, and fatigue resistance.

Manufacturers favor the superior thread quality, accuracy, finish, and improved mechanical properties of rolled threads. No scrap, lower labor participation, and lower tool cost per thread produced all come together in a tried-and-true formula that delivers reduced costs. Static tensile tests have reported increases in the ultimate strength of the threads of approximately 30%. Due to the high precision and accuracy in the thread rolling tools, thread rolling inherently maintains the accuracy of the original setup during long runs of high-speed production.

The GEN TURN 52 GTS is a 2.047” (52mm) bar diameter twin spindle CNC production turning center with a fully synchronized C-axis on both the main and sub-spindle. This machine configuration produces shorter cycle times because the counter spindle works simultaneously with the main spindle. For many workpieces, the GTS is more efficient than a twin-turret twin-spindle machine that costs twice as much.

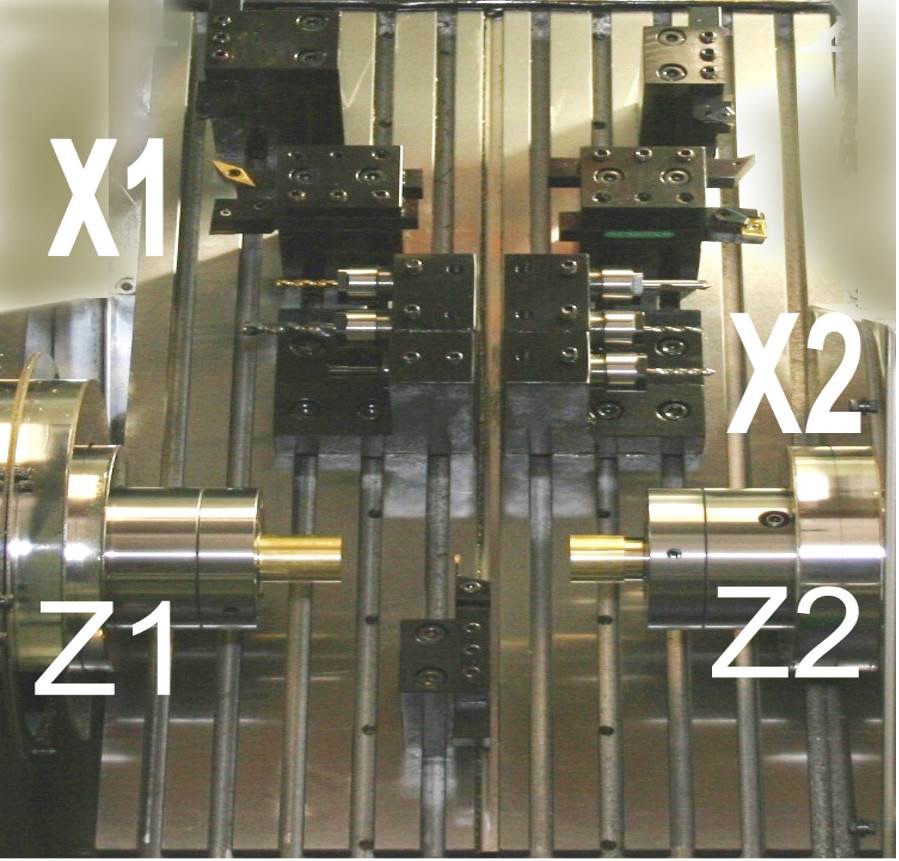

The 52 GTS features dual parallel gang slides sitting side-by-side, allowing tool placement flexibility, including driven tools. Both the main gang slide and the sub-spindle gang slide work completely independently, allowing for shorter cycle times because the front and the back of a workpiece can be machined at the same time. The sub-spindle features a finished parts ejector and programmable air blast to clean the collet. The included parts catcher and parts conveyor transfer the finished workpiece outside of the work envelope. A steel link-belt chip conveyor is included with the machine to dispose of the chips.

Contact Expand Machinery at 818-349-9166 for questions on your material processing needs and for your manual and CNC lathe and milling machines, as well as your robotic work handling requirements.