In recent times, we have seen a growth in the usage of composite materials. It seems like they are all over the place, and we cannot help but interact with them in varied forms. These materials have been around from time immemorial and widely used to manufacture almost everything from sturdy tennis rackets to sleek aircraft.

Composite materials are a combination of two or more components. That makes it more robust than its individual component. A prominent benefit inherent in them is that they are lightweight. The diverse molding techniques of composite materials make it a flexible work material for designers as they can use lesser material for multiple designing options. Although machining composite materials can be daunting it becomes easy with the correct selection of CNC machines, their settings, and innovative processes.

Before diving into specifics to make the material machining process smoother, we must consider a few basic concepts about machining composite materials.

Understand the Components

We first look at the components of composite materials before moving on to the production method. We can sub-divide these elements into two categories: Matrices and Reinforcements.

A fiber-reinforced plastic composite is composed of carbon, glass, aramid, or other fibrous synthetic material in conjunction with a resin, whether a thermoplastic system or a thermoset. Various ceramic and metal powders are added to the polymer matrix to act as reinforcing agents, which alter the properties of the composite in desired ways. We can use other chemicals like silica or silicon dioxide to implement the qualities of a composite material.

Use Waterjet Cutting for Delicate Materials

Waterjet cutting is a powerful and accurate way to cut delicate materials like composites. The advantage of waterjet cutting is it lends itself well to machining applications where precise dimensions are required. With the help of waterjet cutting, we can take tight tolerances and make adjustments quickly. This feature makes it easy to procure parts that fit together perfectly, and we will not have to remake parts if they are slightly larger or smaller than expected.

Machining Process Improves with Practice

Machining composites can be arduous. Composites, with their fiber-based reinforcing, create new problems for the craftsmen. Composites have a lower tool life due to their abrasive nature. With time and practice, machinists can better understand the material by reading the erosion patterns on the cutting tools. We can learn the material reactions by trial and error, and what we learn will be a valuable tool for future projects.

For example, climb cutting may or may not always result in quality cuts; in these scenarios, machinists can try switching to traditional side milling or perhaps using a brad-point tool instead to avoid delamination on certain composite materials.

Selecting Proper Cutting Tool

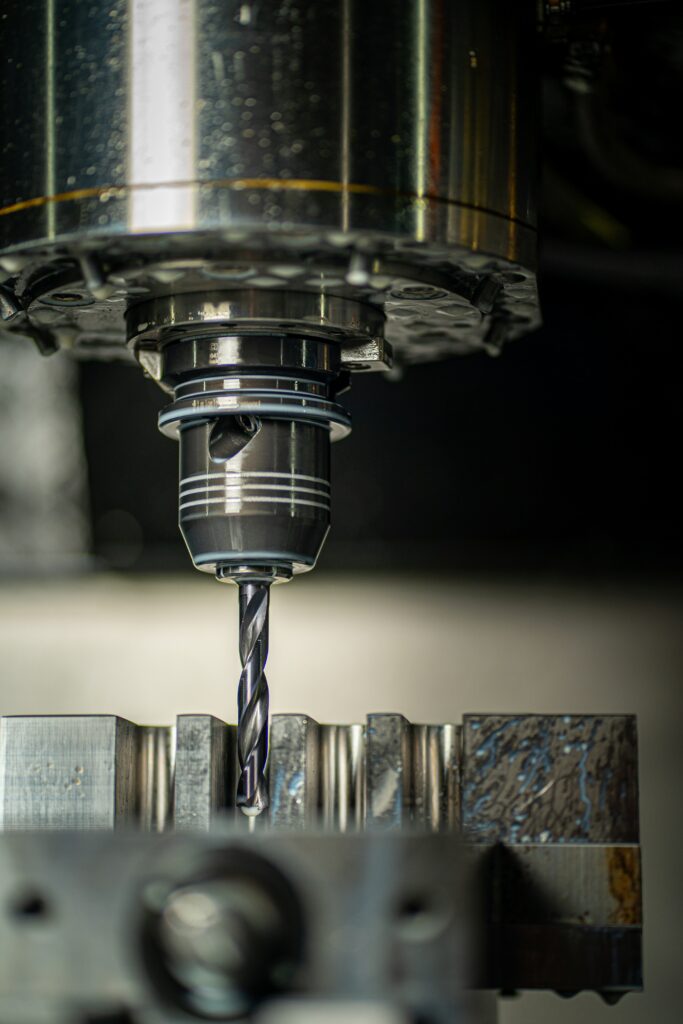

Machining composites like carbon fiber reinforced polymer use abrasive cutting processes to cut the assembly parts on a CNC milling machine. It is tricky to divide material with this technology because it tends to break more often than traditional steel during production runs. Indexable milling cutters made from carbide and PCD tips provide an exceptionally long lifespan compared to carbide without any price increase in tool cost.

These tools also give better results in the surface finish. That means our finished product will have higher quality parts. These cutting tools come in handy to create complicated designs and geometries on our parts— thus, they are beneficial for creating high-tech assemblies.

Prevents Delamination while Drilling

Composite materials comprise layers of material that can easily split apart or delaminate during drilling. We must consider the composite’s surface hardness and drilling speed while choosing which bit to use. That is because the materials need to be sufficiently strong to reduce problems such as splintering during cutting. Drill bits made particularly for composites prevent delamination while drilling.

Trim with Sharp Tools

Sharp tools are a necessity when it comes to manufacturing composite materials. Compressive helix cutters with intricate designs prevent delamination and hanging while trimming. We can use endmills for slotting, pocketing, and trimming orthogonal cuts. For making holes, diamond drills complete an edge chamfer and have radii to limit splintering during the breakthrough process.

Considering Necessary Parameters

When dealing with large, rigid surfaces on a CNC machine, we must be aware that the speed of the spindle and feed rate can have drastic effects. Assuming we want to avoid having huge gaps in the finish or providing your lathe with the wrong amount of power, we must maintain specific metrics when doing these types of jobs.

Before cutting composite materials, we must determine where to cut, the size piece of CNC machinery we are working with, and the depth of the removal of the section at a given time.

Choosing Proper Tool Holder

Successful CFRP machining processes require high-quality diamond and diamond-coated cutting tools. However, they may not produce satisfactory results without the proper tool holder for a secure grasp.

Safeguards Machine from Harm with Dust Control

Dust is a leading cause of many issues with composite machining. Compounds like polyester, tri-plex glass fibers all produce harmful dust during the manufacturing process. It is vital to protect the well-being of our workers and the integrity of our machinery. If we have a buildup of residue, it will often clog up our machine’s controller, causing errors.

On the other hand, carbon fiber dust is dangerous to electronic gadgets because it is a good conductor of electricity. If we do not control the dust level, it can cause machine circuits to short out, and digital equipment will malfunction. Carbon fiber particles can also cause lung injury.

Ascertain Proper Cooling

Coolant lubricates the equipment, removes heat and dust from the workplace, and acts as a catalyst on some composites. But to achieve that, we can only use specific and stated lubricants for composites! Others have an abrasive effect when mixed with composite dust. That will lead to recutting and tool damage that you can otherwise avoid.

Cold air guns eliminate composite dust while Cold Air-Assist tools (CAATs) capture any remaining dust left in the cutting zone – no matter how small it may be!

Conclusion

Composites are probably the most challenging materials a machinist will encounter during fabrication. They are gritty and filled with dust. It can be challenging to grasp them with tools because cutting into these composites requires something extraordinary.

We need expert toolmakers who can quickly make adjustments when they notice that something is amiss. We also need an array of advanced features on your equipment to handle composite materials effectively. If we think outside the box and use some elbow grease, we can devise innovative solutions.

About the Author

Vincent Hua

Vincent Hua

Vincent Hua is the Marketing Manager at TSINFA. He is passionate about helping people understand high-end and complex manufacturing processes. Besides writing and contributing his insights, Vincent is very keen on technological innovation that helps build highly precise and stable CNC Machinery.