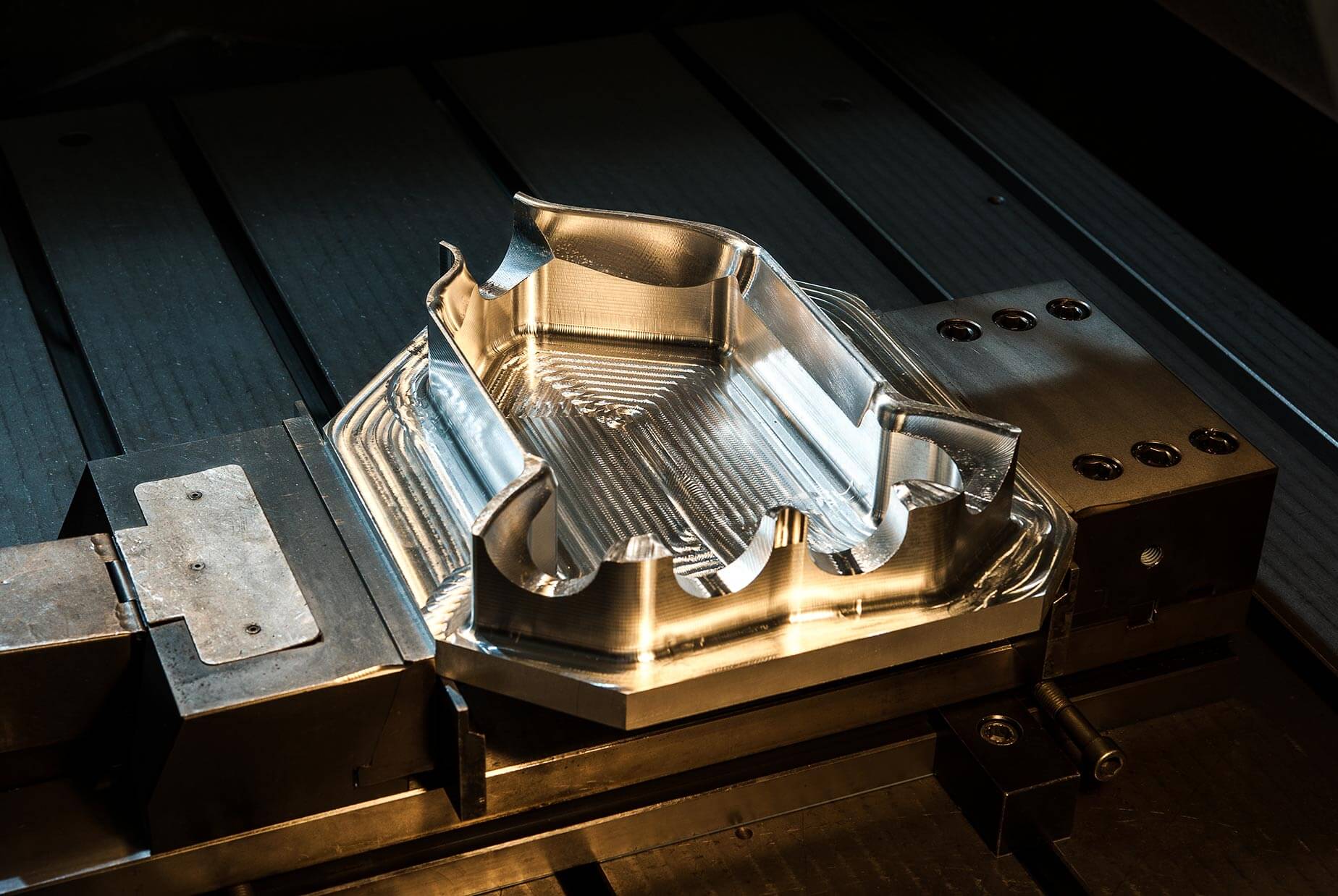

Our modern society is enhanced by the many molded parts and components that we use every day. The machines used to make the molds that make these parts, must be able to machine complex geometries efficiently in difficult to machine materials by combining high feed rates with minute moves to produce the fine surface finishes necessary to preclude the need for labor intensive hand finishing. These precision die sets then are used to produce countless automotive, medical, packaging, electronic and consumer products for our use and enjoyment.

The GEN MILL 5127 is capable by design of undertaking this demanding mold work though a series of strategic features that are standard on the machine. Machine rigidity is critical in mold making and the GEN MILL has that in spades by delivering to you a high strength cutting platform. Heavy-duty cross-roller linear ways support all three axes providing not only high-rigidity and strength, but also enhancing table load capacity. The cross-roller ways deliver twice the rigidity that is offered by standard ball-bearing ways and provide you with greater cutting capability and extended tool life. The cutting tool is supported in a Big-Plus dual contact high-performance precision ground spindle that features increased tool rigidity, reduced tool runout, superior tool length repeatability, and both increased cutting capability and tool life. All these features are critical to your success in the mold making industry.